For the best lock products, you should choose the Sinte […]

For the best lock products, you should choose the Sintered Parts Lock. This type of lock part is made of 304 stainless steel and features a tolerance of +0.05mm. The hardness of the parts is 50-55HRC and they feature low oxygen content and irregular shapes. The MewuDecor Brand manufactures MIM-based products and offers customization services. These parts are designed to meet the needs of various industries and can be used in any lock.

The first step in the manufacturing of sintered parts is sintering. Sintering is the process of bonding the powder grains together. For iron-based PM parts, sintering takes place at a temperature of around 2020-2100degF. Higher temperatures are used to change the part's properties. High-temperature sintering can produce a highly engineered part with exceptional performance. Its performance can be improved by up to ten times.

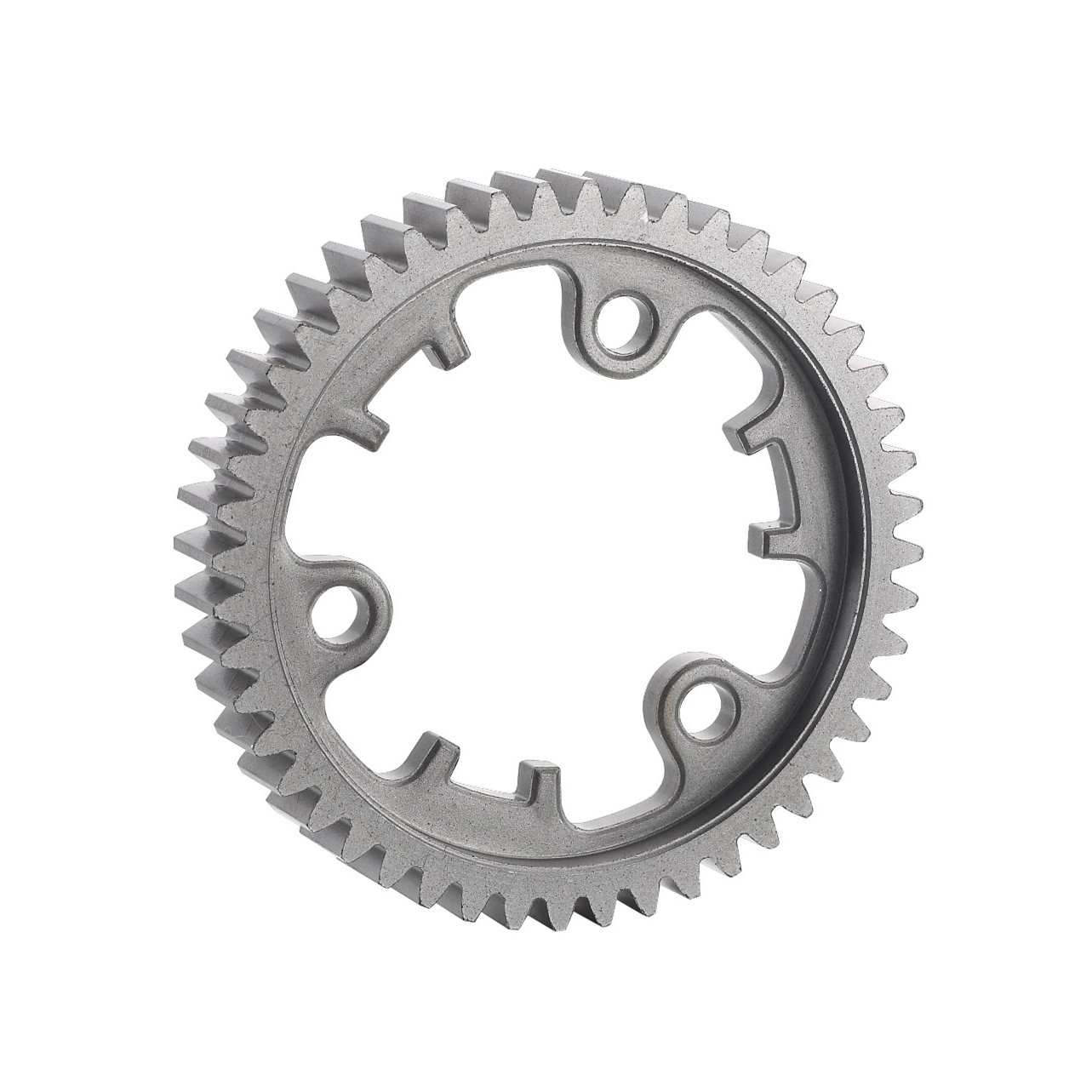

Another type of Sintered Parts Lock is made from powder metal. This material is very durable, as it can withstand high tensile loads. Its superior strength and durability make it an excellent choice for the automotive industry. Today, modern automobiles are all about weight, so lightweight and durable components are important in any vehicle. Also, sintered metal has a higher impact strength than steel and wrought iron. Its superior strength is useful for a wide range of applications, including brackets, hooks, and many other items.

Sintered Parts are made from powdered metal. The powder is melted in a high-temperature furnace, and the parts are then compressed and molded into shape. Some of these parts are used in the automotive industry, in the food and beverage industry, and in outdoor power equipment. You can even find parts made of stainless steel in locks and lock accessories. You can get the same benefits for less than half the price of wrought iron and steel.

It offers advanced material and process solutions for the power tool, lawn & garden, and outdoor power equipment industries. Its sintered metal parts are ideal for the construction and appliance industry. Additionally, they are highly corrosion-resistant and can be used for any industrial application. However, the best part of a Sintered Parts Lock is its ability to resist wear and tear.

Metal Injection Molding is a popular method of producing parts in the automotive industry. It allows you to create complex shapes from metal powder by using a compacting press. In addition to lock and keymaking, metal-injection molding is used to manufacture a wide variety of components for various other industries. Some of these products include pawls and mechanical pawls. These types of lock and key are the most common ones in the automotive industry.